Custom BLDC Motor Solution

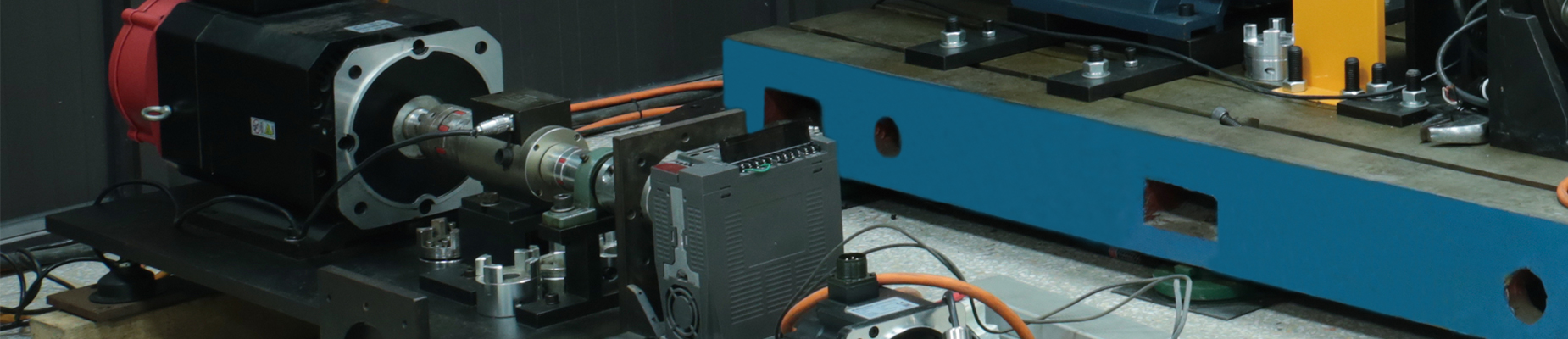

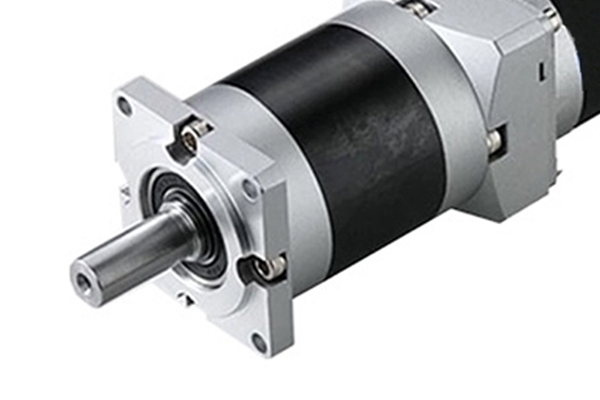

Looking for a BLDC motor tailored to your specific application? At BLDC.com, we specialize in designing and manufacturing custom brushless DC motors to meet your exact needs. Whether you're building cutting-edge robotic arms, lightweight drones, high-efficiency e-mobility solutions, or rugged industrial automation systems, our engineering team delivers end-to-end customization, ensuring seamless integration, optimal performance, and long-term reliability.

What Can You Customize?

You can customize a wide range of brushless DC motor parameters, including operating voltage, speed range, power output, square flange size, and motor lead configuration, to ensure optimal compatibility with your applications. In addition, we offer shaft type customization (such as optical shaft, keyway shaft, stepped shaft, hollow shaft, etc.) and gearbox integration (planetary, inline, right angle, or worm gearbox) to match your mechanical and torque requirements.

Voltage

Available in 12V, 24V, 36V, 48V, 72V, 96V, and 110V, compatible with a wide range of BLDC motor power systems.

Recommendations:

- 12V / 24V: Ideal for portable devices, battery-powered equipment, small robots, and light-duty automation.

- 36V: Common in mid-range e-mobility solutions such as e-bikes and compact AGVs.

- 48V / 72V: Widely used in high-efficiency electric vehicles, industrial robotics, and AGVs.

- 96V: Suitable for high-power industrial drives, electric forklifts, and large automation systems.

- 110V: Used in custom machinery and heavy-duty applications requiring higher voltage and reduced current draw.

Speed

Offered in 2000rpm, 3000rpm, 6000rpm, and variable speeds from 1 to 3000 rpm, with lower speeds achievable through the gearbox.

Recommendations:

- Fixed speeds (2000rpm/3000rpm): Best for stable loads and simple control requirements.

- High speed (6000rpm and above): Ideal for applications requiring fast response and low inertia.

- Wide speed range (1~3000rpm): Suitable for intelligent or programmable systems; typically used with a controller or driver for closed-loop control.

- Low-speed, high-torque applications: BLDC motors aren’t ideal for direct low-speed drive, and a gearbox is typically used to achieve the required torque.

Square Flange Size

Offering square flange sizes of 57mm, 80mm, 86mm, 110mm, 130mm, 180mm, and 220mm, designed to match different BLDC motor and application needs.

Motor Lead

Fully customizable based on your wiring layout or motor controller interface.

Motor Shaft

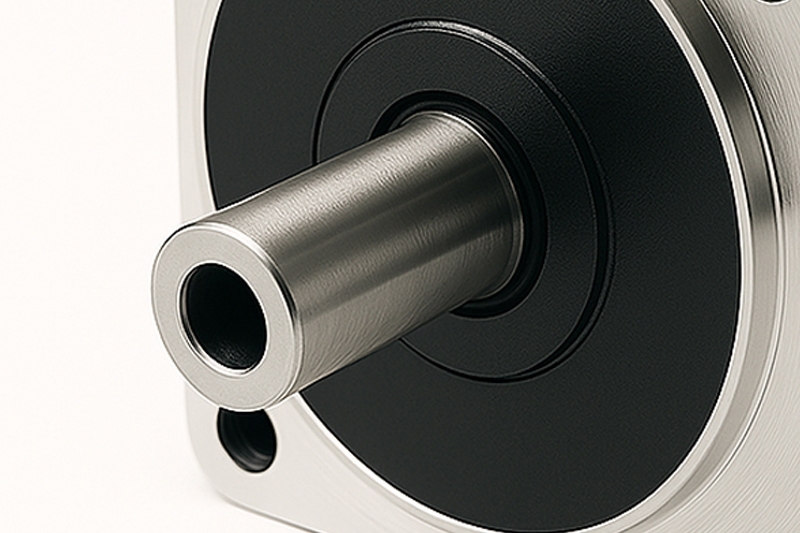

Optical Shaft (Default)

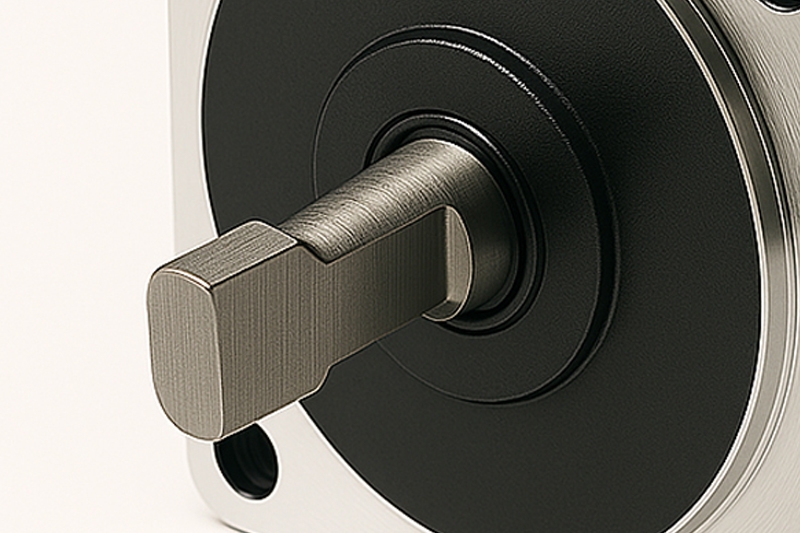

Keyway Shaft (Default)

Stepped Shaft

Hollow Shaft

Special Shaped Shaft

Tapered Shaft

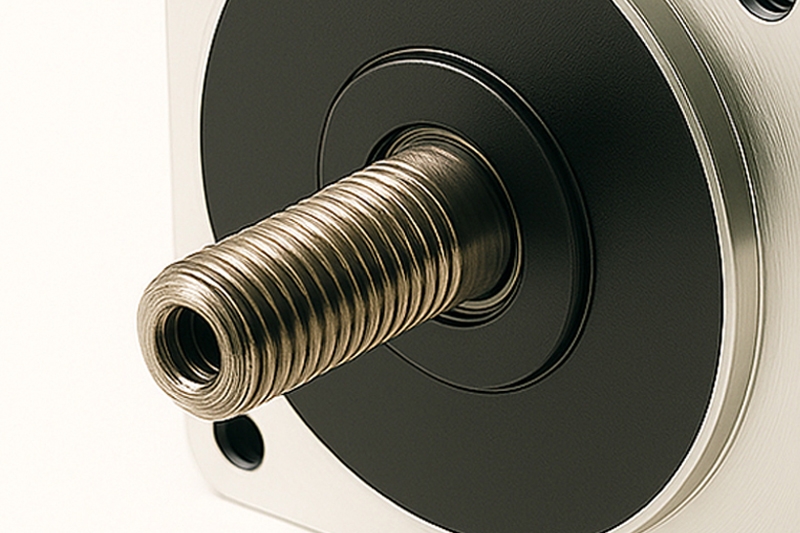

Threaded Shaft

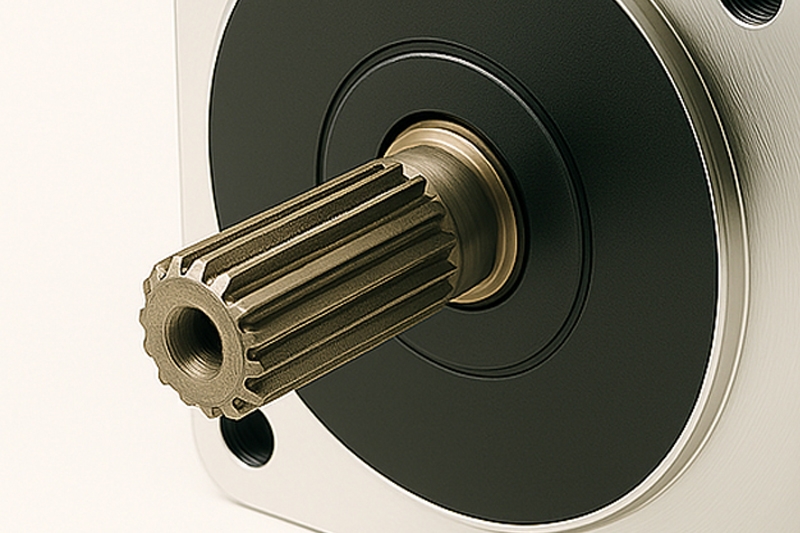

Spline Shaft

Milled Flat Shaft

Drilled Shaft

Cross Groove Shaft

Gear Shaft

Gearbox Type

Standard Gearbox

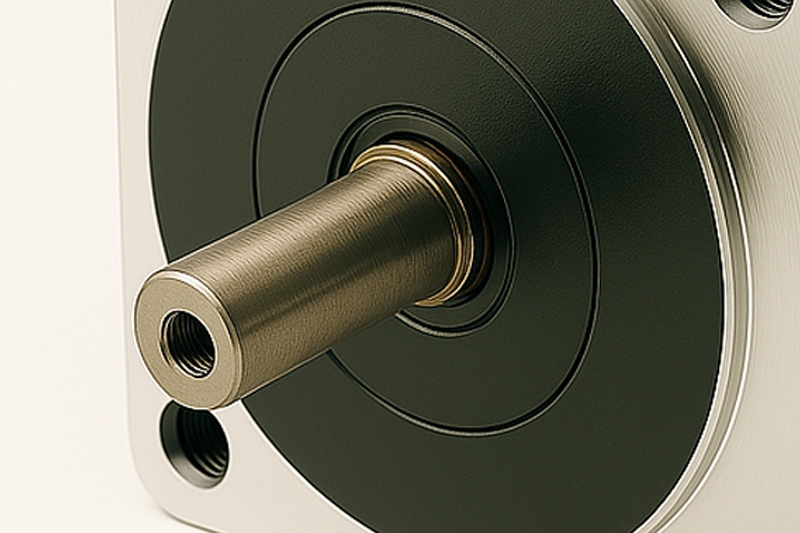

(Blind-hole Type)

Standard Gearbox

(Through-hole Type)

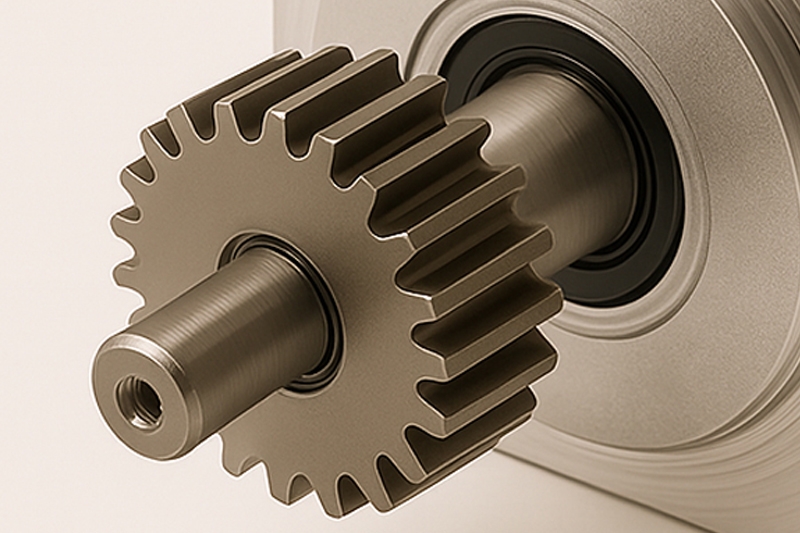

Planetary Gearbox

Inline Gearbox

Right Angle Gearbox

Worm Gearbox

Gear Ratio

| Gearbox | Gear Ratio |

| Standard Gearbox (Blind-hole Type) |

3:1, 5:1, 7.5:1, 10:1, 12.5:1, 15:1, 18:1, 20:1, 25:1, 30:1, 36:1, 40:1, 50:1, 60:1, 75:1, 90:1, 100:1, 120:1, 150:1, 180:1, 200:1 |

| Standard Gearbox (Through-hole Type) |

3:1, 5:1, 7.5:1, 10:1, 12.5:1, 15:1, 18:1, 20:1, 25:1, 30:1, 36:1, 40:1, 50:1, 60:1, 75:1, 90:1, 100:1, 120:1, 150:1, 180:1, 200:1 |

| Planetary Gearbox | 4:1, 5:1, 7:1, 5:1, 10:1, 16:1, 20:1, 25:1, 28:1, 35:1, 40:1, 50:1, 70:1, 80:1, 100:1, 125:1, 140:1, 175:1, 200:1 |

| Inline Gearbox | 3:1, 4:1, 5:1, 7:1, 9:1, 10:1, 12:1, 15:1, 16:1, 20:1, 25:1, 32:1, 40:1, 50:1, 64:1, 80:1, 100:1, 120:1, 150:1, 200:1 |

| Right Angle Gearbox | 3:1, 4:1, 5:1, 8:1, 9:1, 10:1, 12:1, 15:1, 16:1, 20:1, 25:1, 32:1, 40:1, 50:1, 64:1, 80:1, 100:1, 120:1, 150:1, 200:1 |

| Worm Gearbox | 7.5:1, 10:1, 15:1, 20:1, 25:1, 30:1, 40:1, 50:1, 60:1, 80:1, 100:1 |

*Different torques can be obtained by adding a gearbox.

Other Custom Items

- Motor Waterproof Rating: IP54 and IP65

- Controller Communication Interface/Method: RS485, CAN Bus

- Brake: 24V or 48V Brake

- Encoder: Incremental Rotary Encoder or Absolute Rotary Encoder

Customization Process

Request Submission

Submit your application details and requirements through the Contact Us form or email us directly at sales@bldc.com.

Technical Consultation

Our engineers will review your requirements, evaluate key parameters, and provide a tailored solution for optimal performance and reliability.

Proposal & Quotation

We provide detailed technical drawings, specifications, and a clear quotation to help you evaluate the solution with confidence.

Prototype Development

Sample BLDC motors are manufactured according to the approved design and rigorously tested to verify performance, functionality, and reliability.

Customer Feedback & Optimization

You evaluate the prototypes in your application and share feedback; based on your input, we fine-tune the parameters or performance to meet your needs.

Mass Production

Upon final approval, we proceed with bulk production, followed by strict quality checks and on-time delivery.