Close

-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Close

Menu

Close

- Home /

- Shop /

- BLDC Motors /

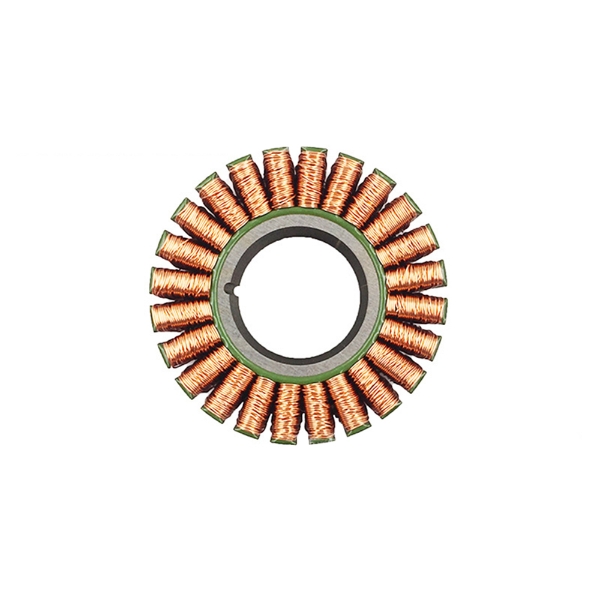

- 40W 24V Frameless BLDC Motor, 100 rpm

Write your own review

Related products

9W 12V Frameless BLDC Motor, 950 rpm

BLDC-FBD-2806

This 9W 12V frameless BLDC motor offers high performance within a compact and lightweight design, achieving a nominal speed of 950 RPM. Drawing 0.81A at its rated voltage, the motor delivers consistent performance while ensuring energy-efficient operation.

$64.89

12W 16V Frameless BLDC Motor, 200 rpm

BLDC-FBD-4310

This 12W frameless brushless DC motor delivers high torque and smooth operation at a rated speed of 200 rpm and a voltage of 16V. The frameless construction, comprising only the stator and rotor, makes this motor easy to integrate into custom mechanical assemblies.

$86.25

30W 24V Frameless BLDC Motor, 200 rpm

BLDC-FBD-5225

This high-performance 30W 24V frameless brushless DC motor is engineered to deliver exceptional torque at a rated speed of 200 rpm and 24V input. With its compact, frameless construction, the motor allows for flexible mechanical integration into custom assemblies and tight spaces.

$113.86

100W 24V Frameless BLDC Motor, 140 rpm

BLDC-FBD-10025

This 100W frameless brushless DC motor delivers a rated torque of 6.9 Nm at 140 rpm, operating efficiently on a 24V supply. Its robust torque output and compact form factor make it especially well-suited for different applications.

$315.68

Precision BLDC Motors for Robotics, EVs and Automation

INFORMATION

RESOURCE

CUSTOMER SERVICE

Copyright © 2026 BLDC.com. All rights reserved.