Close

-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Close

Menu

Close

- Home /

- Shop /

- BLDC Motors /

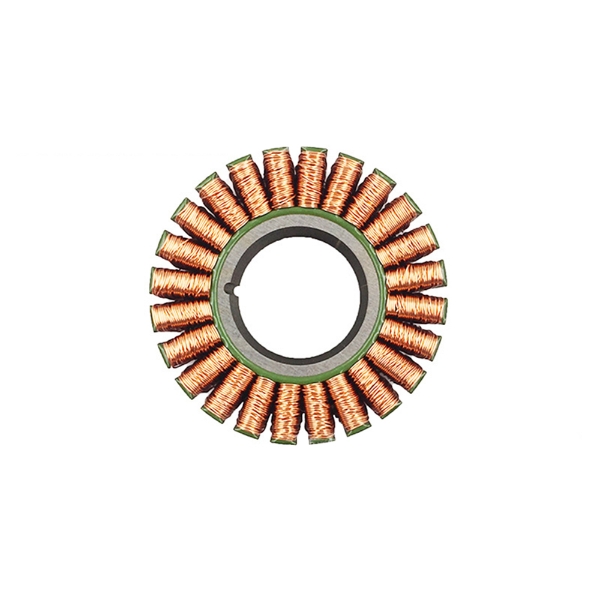

- 12W 16V Frameless BLDC Motor, 200 rpm

Write your own review

Related products

6W 12V Frameless BLDC Motor, 350 rpm

BLDC-FBD-3510

With a rated speed of 350 RPM and a voltage rating of 12V, this compact 6W 12V frameless brushless DC motor offers consistent performance while maintaining low power consumption, ideal for battery-powered and energy-sensitive systems.

$79.86

9W 12V Frameless BLDC Motor, 950 rpm

BLDC-FBD-2806

This 9W 12V frameless BLDC motor offers high performance within a compact and lightweight design, achieving a nominal speed of 950 RPM. Drawing 0.81A at its rated voltage, the motor delivers consistent performance while ensuring energy-efficient operation.

$64.89

30W 24V Frameless BLDC Motor, 200 rpm

BLDC-FBD-5225

This high-performance 30W 24V frameless brushless DC motor is engineered to deliver exceptional torque at a rated speed of 200 rpm and 24V input. With its compact, frameless construction, the motor allows for flexible mechanical integration into custom assemblies and tight spaces.

$113.86

40W 24V Frameless BLDC Motor, 100 rpm

BLDC-FBD-8110

With a rated speed of 100 rpm, this 40W 24V frameless brushless DC motor is ideal for systems requiring fine motion control and quiet operation. Its frameless design allows for seamless integration into space-constrained systems such as UAV gimbals, precision instrumentation, medical devices.

$172.29

Precision BLDC Motors for Robotics, EVs and Automation

INFORMATION

RESOURCE

CUSTOMER SERVICE

Copyright © 2026 BLDC.com. All rights reserved.