3 phase BLDC motor operates at 12V, 24V, 36V, or 48V DC, delivering 250W of rated power, 3000 rpm speed, and 0.8 Nm torque. With an 86mm square flange, this brushless electric motor provides precise control of torque and speed, featuring high efficiency and controllability.

Specification

| Model |

BLDC-D5BLD250 |

| Rated Power |

250W |

| Rated Voltage |

12V DC |

24V DC |

36V DC |

48V DC |

| Matched Controller |

BLDC-KVD2412N |

BLDC-BLD750 |

| Rated Current |

26.06A |

13A |

8.59A |

6.51A |

| Phase |

3 phase |

| Rated Torque |

0.8 Nm |

| Max. Torque |

2.39 Nm |

| Rated Speed |

3000 rpm for standard (or 2000 rpm when matching the worm gearbox) |

| No-load Speed |

3300 rpm |

| No-load Current |

<6.2A |

<4.13A |

<6.2A |

<3.11A |

| Working Efficiency |

71% |

85% |

| Square Flange Size |

86 mm |

| Insulation Grade |

F |

| Protection Grade |

IP54 |

| Motor Lead Length |

1 meter |

| Certificate |

CE, RoHS, ISO |

| Weight |

3 kg |

Note: Power, voltage, speed, shaft, motor length, and motor lead of BLDC motors can be customized.

Features

- Stable Speed Control: The 250W BLDC motor maintains a set speed by continuously comparing feedback signals and adjusting voltage, ensuring consistent performance even with load changes.

- Compact & High Power: Uses a permanent magnet rotor in a 3 phase design, delivering a thin profile with high power density.

- Wide Speed Range: It offers a broader speed control range than AC motors and inverters, providing strong torque from low to high speeds without brushes.

- Energy Efficient: Permanent magnet rotor reduces rotor losses, cutting power consumption by over 20% compared to variable frequency induction motors, supporting energy savings.

- Built-in Protection: Brushless DC motor includes safety features to protect the equipment system.

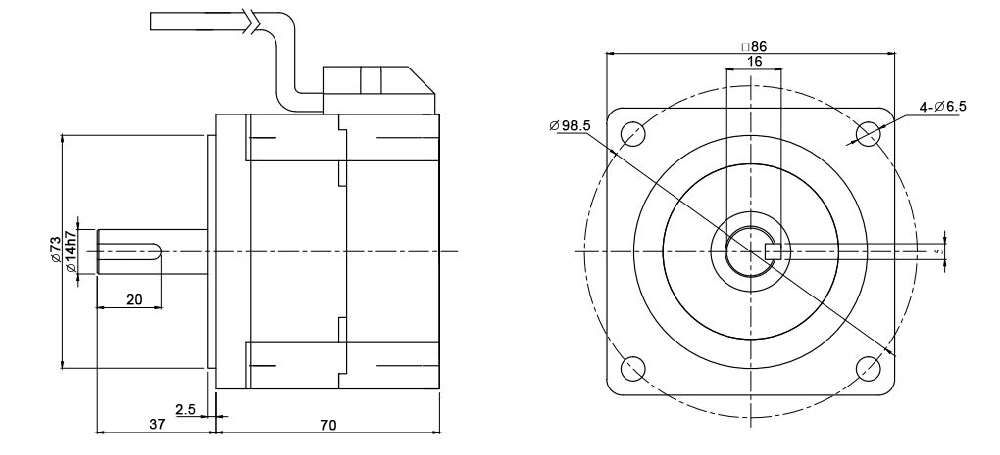

Dimension (Unit: mm)

Speed - Torque Curve

- Instantaneous maximum torque line: This torque represents the peak load impact when the motor starts. If exceeded, the driver’s over-current protection will trigger, stopping the motor.

- Short-time operation area: The BLDC motor can operate briefly within this torque range at various speeds. Prolonged operation may cause overheating, potentially leading to motor shutdown or damage.

- Rated operating torque line: At different speeds, this torque level is the electric DC motor’s rated load, allowing long-duration operation without issues.

- Continuous operating area: The brushless motor can run continuously within this zone at varying speeds, maintaining stable operation.

Line Define

| Power Wire |

Hall Wire |

| Red |

U |

Red |

5V |

| Yellow |

V |

Black |

GND |

| Black |

W |

Blue |

Hu |

| Green |

Hv |

| White |

Hw |

Applications

Q: What is a BLDC motor?

A: A BLDC motor, or Brushless DC motor, is a type of electric motor that operates without the brushes and commutator found in traditional DC motors. Instead, it uses motor controllers to switch current in the motor windings, generating a rotating magnetic field that drives the rotor. The rotor typically contains permanent magnets, while the stator holds the windings. BLDC electric motors offer several advantages, including higher efficiency, longer lifespan, and lower maintenance due to the absence of brush wear. They also deliver precise speed and torque control, making them ideal for applications in robotics, drones, electric vehicles, HVAC systems, and industrial automation. Brushless DC motors come in two main types: inrunner and outrunner, depending on whether the rotor is inside or outside the stator. With their compact size and high power-to-weight ratio, BLDC motors are widely used in modern devices requiring reliable, efficient, and quiet motor performance.