Close

-

You have no items in your shopping cart.

- Register

- Log in

- Wishlist

- Shopping cart

Close

Menu

Close

- Home /

- Shop /

- BLDC Motors /

- 48V/72V/96V 3000W BLDC Motor

Write your own review

Related products

24V/36V/48V 600W BLDC Motor

BLDC-110-600W

With a rated power of 600 watts, the 24V/36V/48V 600W BLDC motor provides optimal efficiency and output for systems requiring high torque and consistent performance. Featuring a rated torque of 1.91 Nm and a maximum torque of 5.73 Nm, this high-torque BLDC motor is ideal for applications requiring precise control.

$505.88

24V/36V/48V 750W BLDC Motor

BLDC-80-750W

The 750W BLDC motor is available in multiple voltage configurations, including 24V, 36V, and 48V, providing flexibility to meet diverse power requirements. With a rated speed of 3000 RPM, this 3-phase motor is optimized to deliver reliable performance in demanding environments.

$352.77

24V/36V/48V 1000W BLDC Motor

BLDC-110-1000W

With a 3-phase brushless DC configuration, this 1000W BLDC motor is designed for high-performance applications with a rated speed of 3000 RPM. This motor is available with multiple voltage options, including 24V, 36V, and 48V, allowing for flexibility in different systems and power requirements.

$415.85

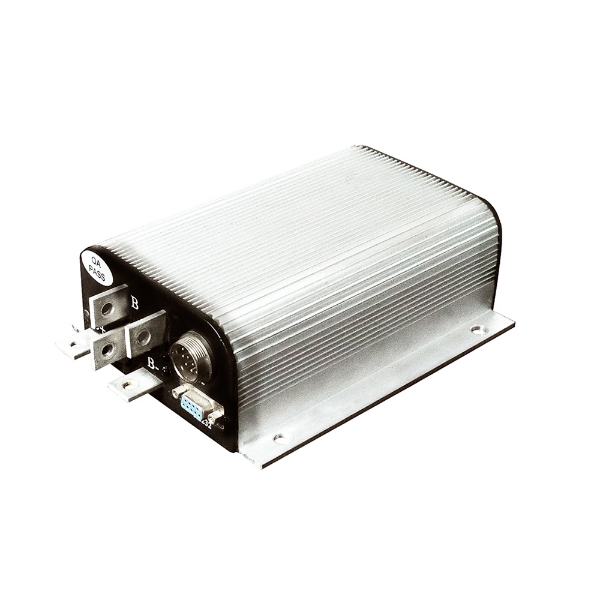

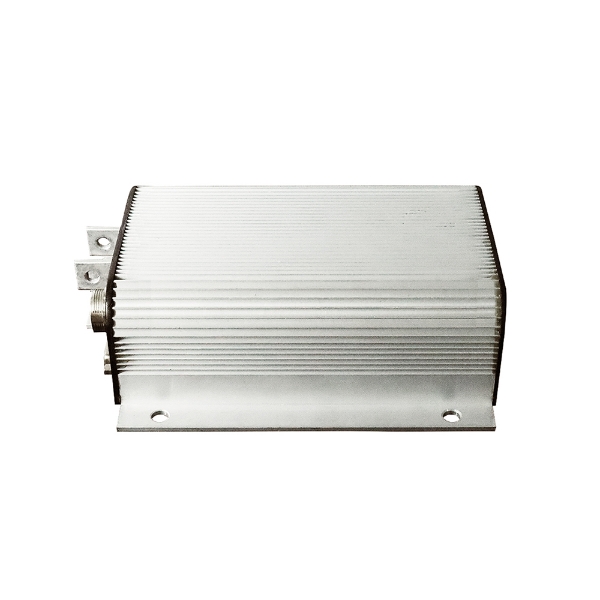

BLDC Motor Controller for 24/48/72/96V BLDC Motor

BLDC-KBL

Capable of handling power outputs from 400W to 10kW, this BLDC motor controller can manage and control brushless motors across a wide voltage range of 24V, 48V, 72V, and 96V. The controller features a sophisticated microprocessor for precise, reliable operation, supporting speeds up to 40,000 RPM.

$395.52

Precision BLDC Motors for Robotics, EVs and Automation

INFORMATION

RESOURCE

CUSTOMER SERVICE

Copyright © 2026 BLDC.com. All rights reserved.