The 750W brushless DC motor is a high-performance solution designed for electric vehicles, offering a 3-phase with a rated speed of 3000 RPM and 2.39 Nm rated torque (max. torque of 7.16 Nm). Available in 24V, 36V, and 48V configurations, it provides flexibility for various power needs. When paired with a matching motor controller and gearbox, the system enhances torque and power delivery, making it ideal for demanding applications.

Specification

| Model |

BLDC-D5BLD750-24A -30S |

BLDC-D5BLD750-36A -30S |

BLDC-D5BLD750-48A-30S |

| Rated Power |

750W |

| Rated Voltage |

24V DC |

36V DC |

48V DC |

| Matched Controller |

BLDC-BD100 |

| Rated Current |

39A |

26.04A |

19.52A |

| Phase |

3 phase |

| Rated Torque |

2.39 Nm |

| Max. Torque |

7.16 Nm |

| Rated Speed |

3000 rpm for standard (or 2000 rpm when matching the worm gearbox) |

| No-load Current |

<9.2A |

<8.13A |

<6.5A |

| Working Efficiency |

85% |

| Square Flange Size |

86 mm |

| Insulation Grade |

F |

| Protection Grade |

IP54 |

| Certificate |

CE, RoHS, ISO |

| Weight |

8 kg |

8 kg |

4.5 kg |

Note: Power, voltage, speed, shaft, motor length, and motor lead of BLDC motors can be customized.

Features

- Stable Speed Control: The 750W BLDC motor maintains consistent speed by dynamically adjusting voltage based on feedback signals, ensuring steady performance under varying loads.

- Compact & High Power: Features a 3-phase design with a permanent magnet rotor, combining a slim profile with high power density.

- Wide Speed Range: Delivers strong torque across a wide speed range, outperforming AC motors and inverters—without the wear of brushes.

- Energy Efficient: The permanent magnet rotor cuts rotor losses, reducing power consumption by more than 20% compared to traditional induction motors.

- Built-in Protection: BLDC motor integrated safety features help safeguard the system and extend equipment life.

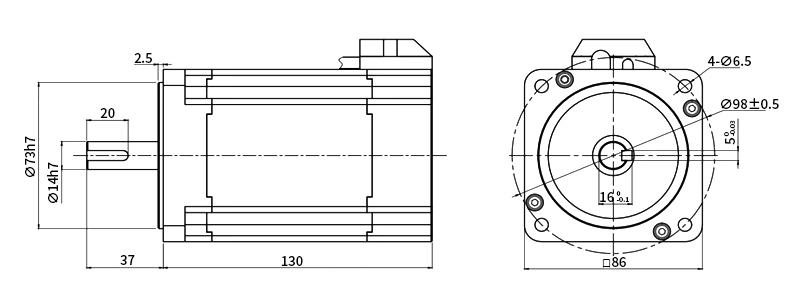

Dimension (Unit: mm)

Speed - Torque Curve

- Instantaneous maximum torque line: This torque represents the peak load impact when the motor starts. If exceeded, the driver’s over-current protection will trigger, stopping the motor.

- Short-time operation area: The BLDC motor can operate briefly within this torque range at various speeds. Prolonged operation may cause overheating, potentially leading to motor shutdown or damage.

- Rated operating torque line: At different speeds, this torque level is the electric DC motor’s rated load, allowing long-duration operation without issues.

- Continuous operating area: The brushless motor can run continuously within this zone at varying speeds, maintaining stable operation.

Line Define

| Power Wire |

Hall Wire |

| Red |

U |

Red |

5V |

| Yellow |

V |

Black |

GND |

| Black |

W |

Blue |

Hu |

| Green |

Hv |

| White |

Hw |

Applications

Q: What are the benefits of a BLDC motor?

A: A BLDC motor offers significant advantages, especially in applications like electric bikes, drones, and robotics. Its high efficiency is a major benefit, as it eliminates brushes, reducing energy loss and heat generation. This leads to longer operational hours, lower maintenance costs, and greater reliability. Additionally, BLDC electric motors provide quieter operation and smoother control over speed and torque, making them ideal for performance-sensitive tasks that require precision.

Moreover, these motors are compact and lightweight, making them well-suited for portable devices and space-constrained applications. In electric vehicles, the ability to regenerate braking energy enhances battery life, providing a more sustainable solution. Overall, a BLDC motor delivers cost-effective, efficient, and high-performance operation across a wide range of modern technologies.