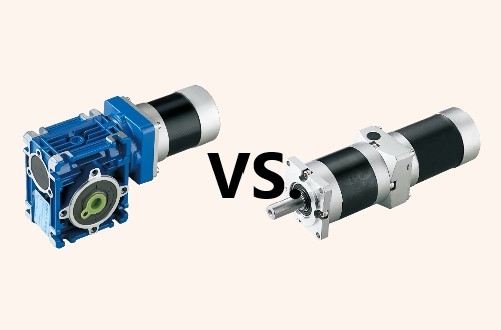

When selecting a motor for your project, it’s essential to understand the different types available, as each has its own strengths and ideal use cases. Two common types of motors used in various applications are BLDC worm gear motors and BLDC planetary gear motors. Though both are brushless DC motors (BLDC), their gear systems and mechanical properties differ significantly. In this blog post, we’ll explore the key differences between these two types of motors, and how to choose the right one for your needs.

What are they?

- A BLDC worm gear motor combines a BLDC electric motor with a worm gear. The worm gear provides a high reduction ratio in a compact space, making it ideal for low-speed, high-torque applications. One key feature is its self-locking ability, preventing reverse rotation, which is useful in lifts, conveyors, and some robotic systems.

- A BLDC planetary gear motor uses a BLDC motor and a planetary gear system, consisting of a sun gear, planet gears, and a ring gear. This setup offers high efficiency, minimal backlash, and smooth operation. Planetary gear motors are ideal for applications that require both speed and torque, such as robotics, drones, and electric vehicles.

Key Differences

| Feature | Worm Gear Motor | Planetary Gear Motor |

| Gear Mechanism | Consists of a worm and a worm wheel. The worm gear offers a high reduction ratio in a small space, ideal for low-speed, high-torque applications. | Features a sun gear, planet gears, and a ring gear. More efficient at distributing load, suitable for both high torque and speed. |

| Torque and Efficiency | Provides excellent torque at low speeds but is less efficient due to sliding contact between the worm and the wheel, which generates friction and heat. | More efficient than worm gears, as the load is distributed across multiple contact points. Lower friction, making it better for high-speed and high-torque applications. |

| Size and Compactness | Typically more compact due to the high reduction ratio in a small form factor. Ideal for applications where space is limited. | Slightly larger than worm gear motors for the same torque output, but still compact and capable of higher power density. |

| Backlash and Noise | Tends to have more backlash due to the nature of the worm gear interaction, which may result in slight play. Also, the sliding contact generates more noise. | Minimal backlash due to the rolling contact between gears, resulting in higher precision and quieter operation, making it ideal for noise-sensitive applications. |

| Applications | Best suited for applications requiring high torque at low speeds, such as conveyors, lifts, and winches. Self-locking ability prevents reverse rotation. | Ideal for high-speed, high-performance applications like robotics, drones, CNC machines, and medical equipment where precision and reliability are key. |

| Cost and Durability | Generally less expensive, but efficiency losses and wear over time due to friction can lead to higher maintenance costs and a shorter lifespan under heavy load or continuous use. | More expensive but highly durable. Better load distribution and lower friction contribute to a longer lifespan and lower maintenance costs, even under high loads. |

Conclusion: Which One to Choose?

Both the BLDC worm gear motor and BLDC planetary gear motor have distinct advantages depending on your application:

- Choose a worm gear motor if you need high torque at low speeds, require a self-locking mechanism to prevent reverse rotation, or need a compact design for limited spaces. This motor is ideal for low-speed, high-torque applications like conveyors, lifts, and actuators.

- Choose a planetary gear motor if you need high efficiency, higher speeds, minimal backlash, and better torque handling with precision. Planetary gear motors are great for applications where both torque and speed are important, such as robotics, electric vehicles, and industrial automation.

By understanding the differences between these two types of gear motors, you’ll be able to make an informed decision on which one is best suited to your project’s needs.