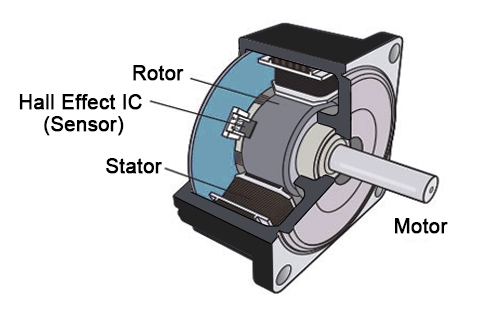

A brushless DC (BLDC) motor consists of three fundamental components: the stator, the rotor, and the electronic controller. The stator remains stationary and contains copper windings arranged in multiple phases. When energized in a precise sequence, these windings generate a rotating magnetic field. The rotor, embedded with permanent magnets, responds to this field and rotates in sync, converting electrical energy into mechanical motion.

The defining feature of BLDC motors is their method of commutation. Traditional brushed motors rely on physical contact between brushes and a commutator to switch current flow through the windings. BLDC motors eliminate this mechanical process entirely. Instead, an external electronic controller determines the timing and phase of current delivery based on the rotor’s position—measured directly via Hall-effect sensors or estimated through back-EMF signals in sensorless configurations. This electronic commutation enables smooth, efficient, and highly responsive operation across a wide range of speeds and load conditions.

With this architecture, the BLDC motor functions not as an isolated component, but as part of an integrated electromechanical system. The synchronization between digital control and magnetic response allows for high precision, low acoustic noise, and improved energy efficiency—making BLDC motors an optimal choice for applications that demand reliability, responsiveness, and minimal maintenance. Backed by deep expertise in motor systems and integration, bldc.com explores how these motors work, what differentiates them from conventional designs, and why they are central to the future of smart motion control.

Electronic Commutation Explained

Traditional brushed motors achieve rotation through the physical switching of current by brushes that rub against a rotating commutator. While simple and cost-effective, this setup generates friction, heat, and electrical noise—factors that lead to lower efficiency and a limited operational lifespan. In contrast, BLDC motors achieve the same directional current switching using digital electronics. The controller switches current through the stator coils in exact phases, creating magnetic fields that interact with the rotor magnets at just the right time.

Electronic commutation involves continuously monitoring or estimating the rotor position and adjusting the phase currents accordingly. This allows for incredibly smooth rotation, efficient torque production, and high-speed capability. It also enables features like regenerative braking, precise torque control, and integration with digital systems for real-time feedback and adaptive performance. The elimination of brush arcing also makes these motors suitable for environments sensitive to electrical interference or where contamination from brush wear would be problematic.

This shift from mechanical to electronic commutation is what gives BLDC motors their edge—not only in terms of performance, but also in reliability, service life, and system integration.

Rotor Configurations: Inner vs. Outer

While all BLDC motors operate on the same principles, their design can vary based on how the rotor and stator are positioned. In an inner rotor configuration, which is the most common, the rotor spins inside a surrounding stator. This layout is compact, thermally efficient, and capable of delivering high torque density, making it ideal for automotive and industrial systems where performance and space efficiency are critical.

Outer rotor designs, on the other hand, reverse this arrangement—the rotor encases the stator and spins around it. This design increases the rotational inertia and provides greater torque at lower speeds, which is beneficial in applications like ceiling fans, gimbals, and drones. The larger rotor diameter helps generate higher torque with less current, and the slower rotational speed often contributes to quieter operation and greater mechanical stability.

Choosing between these configurations depends on the application's demands for speed, torque, size, weight, and heat dissipation. Inner rotor motors are generally better for dynamic, high-load environments, while outer rotor motors shine in compact, low-noise, and low-speed systems.

Performance Advantages

The performance advantages of BLDC motors are numerous and well documented. First and foremost is their efficiency: by eliminating friction between brushes and the commutator, BLDC motors convert electrical energy to mechanical energy with far less loss. This is especially valuable in battery-powered systems like electric vehicles or portable electronics, where every bit of efficiency extends operating time.

They also offer greater precision. Because the BLDC motor controller can adjust current flow to each coil individually and in real time, the motor can deliver finely tuned torque and speed. This level of control supports advanced functions such as field-oriented control (FOC), which optimizes performance under varying load conditions, and even sensor fusion with feedback from other systems. Additionally, BLDC motors generate less heat and can operate at higher speeds without sacrificing longevity or stability.

Durability is another key benefit. The absence of brushes means there are fewer parts to wear out, reducing the need for regular maintenance and extending the service life of the motor. This makes them ideal for mission-critical or hard-to-service systems like aerospace components, medical devices, and industrial automation.

Limitations and Design Challenges

Despite their strengths, BLDC motors are not without trade-offs. The most obvious is cost. A complete BLDC system requires not just the motor, but a dedicated controller capable of sophisticated timing and feedback handling. This increases both initial design complexity and component cost, especially in applications that demand sensor integration or advanced control logic.

Designing with BLDC motors also requires a deeper understanding of power electronics and control theory. Tuning motor parameters, managing EMI (electromagnetic interference), and ensuring thermal performance all require careful engineering. In sensorless applications, additional software and signal processing are needed to detect rotor position accurately—especially at low speeds, where back-EMF signals are weak.

Nonetheless, advances in digital signal processors (DSPs), microcontrollers, and power modules are steadily lowering the barrier to adoption. For many companies, the long-term gains in efficiency, performance, and reliability outweigh the upfront investment.

Real-World Applications

The diversity of applications that benefit from BLDC technology is a testament to its versatility. In electric vehicles, BLDC motors are used in traction drives, pumps, fans, and compressors—anywhere efficiency and responsiveness are critical. In drone and aerospace systems, their lightweight and compact form factor delivers high thrust-to-weight ratios and agile control. In household appliances like washing machines, vacuum cleaners, and HVAC compressors, they contribute to reduced noise, smoother operation, and lower energy consumption.

In the manufacturing sector, BLDC electric motors are used in robotics, conveyors, machine tools, and actuators—often in demanding environments where uptime and repeatability are essential. Their ability to integrate seamlessly with programmable logic controllers (PLCs), feedback sensors, and smart diagnostics makes them well-suited to Industry 4.0 initiatives and modern automation strategies.

Conclusion

BLDC motors are more than a modern alternative to brushed motors—they represent a fundamental upgrade in how we generate and control motion. Their ability to operate without mechanical wear, deliver high efficiency, and integrate seamlessly into digitally controlled systems makes them indispensable in today’s energy-conscious and performance-driven world.

As electronic control continues to evolve and component costs fall, BLDC motors are poised to become even more ubiquitous. Whether driving a car, stabilizing a drone, or powering the quiet fan in your living room, these motors are shaping the future of motion—precise, reliable, and remarkably efficient.