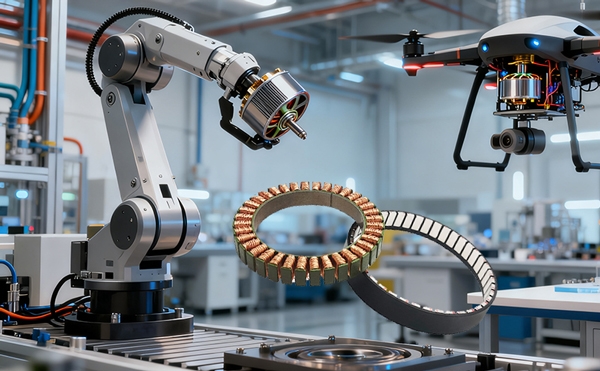

In recent years, frameless brushless DC (BLDC) motors have garnered significant attention in industries such as robotics, aerospace, medical equipment, and automated machinery, where compact, lightweight design and high performance are paramount. Unlike traditional motors, which require complete components, frameless BLDC motors only include the essential electromagnetic components: the stator and rotor. This unique structure enables engineers to integrate the motor directly into mechanical designs, offering exceptional flexibility in terms of size, weight, and performance. In this article, we will explore the concept, operating principles, and selection of frameless BLDC motors.

Frameless BLDC Motor Structure

A frameless BLDC motor includes only two main parts: the stator and the rotor, without an external housing or frame.

- Stator: The stator is made of laminated silicon steel sheets wound with copper coils. When powered, it generates a rotating magnetic field.

- Rotor: The rotor contains high-performance permanent magnets that rotate with the magnetic field. Depending on design, it can be an inner-rotor or outer-rotor type.

- No Bearings or Shaft: Unlike housed motors, the frameless type does not include bearings, a shaft, or an enclosure. These components must be integrated into the host machine’s mechanical structure.

How does It Work?

Frameless BLDC motors operate similarly to traditional BLDC electric motors, utilizing electromagnetic interaction between a stator and rotor to generate rotation, but without a housing, bearings, or shaft. The stator contains wound copper coils that, when energized by a controller, generate a rotating magnetic field. The rotor, equipped with permanent magnets, follows this magnetic field, generating torque and motion. Because the motor lacks a frame, it must be directly integrated into a host machine, such as a robot joint or spindle, which provides mechanical support and bearings. This integration reduces weight, size, and inertia, thereby improving efficiency and responsiveness.

Frameless Brushless Motor Advantages

- Compact and Lightweight Design: Frameless BLDC motors eliminate the outer housing and bearings, reducing weight and overall size. This makes them ideal for applications with tight space constraints, such as robotic joints, drones, and medical devices.

- High Power Density: Without an additional frame, the stator and rotor can be directly integrated into the mechanical structure, improving thermal dissipation and allowing higher continuous torque and power output relative to their size.

- Design Flexibility: Engineers can customize frameless BLDC motors to fit specific mechanical configurations. The motor can be embedded directly into the load, enabling optimal balance, reduced inertia, and improved overall system efficiency.

- Enhanced Efficiency and Performance: Direct integration minimizes mechanical losses from couplings or gear systems. The result is higher efficiency, faster response, smoother rotation, and lower noise levels compared to traditional housed motors.

- Improved Thermal Management: Frameless motors allow more effective heat dissipation since the stator can be thermally coupled to the host structure. This provides better temperature control and extends the motor’s operating life.

- Reduced Maintenance Requirements: With fewer mechanical parts, such as bearings or external housings, frameless brushless motors experience less wear and tear. This simplifies maintenance and reduces downtime in long-term operation.

- High Precision and Control: Frameless motors deliver exceptional torque accuracy and smooth motion, making them ideal for precision applications like surgical robots, gimbals, and semiconductor equipment.

- Integration into Advanced Systems: Their adaptable form factor and excellent performance characteristics allow seamless integration into compact, high-performance systems where traditional motors cannot fit.

How to Choose a Frameless BLDC Motor?

Selecting a frameless BLDC motor starts with understanding the application's mechanical and electrical requirements. Because frameless motors rely on an external housing and rotor assembly for support, consider torque, speed, and power requirements. Evaluate integration options—whether directly attached to a gearbox or into custom machinery. Note the motor's size, KV rating, and compatibility with the BLDC motor controller. Because frameless motors typically lack an internal housing, cooling and environmental conditions are crucial. Finally, evaluate accuracy, reliability, and cost to ensure the motor meets performance expectations while seamlessly integrating into your mechanical design.

BLDC.com provides different kinds of frameless BLDC motors below:

|

Product |

SKU |

Nominal Voltage |

Rated Power |

|

|

12V |

6W |

|

|

|

12V |

9W |

|

|

|

16V |

9W |

|

|

|

16V |

12W |

|

|

|

24V |

30W |

|

|

|

24V |

40W |

|

|

|

24V |

100W |

|

|

|

36V |

250W |

|

|

|

24V/48V |

130W/400W |

Frameless BLDC motors combine high performance with adaptability, providing engineers with a solution tailored to specific machine requirements. This design not only improves overall system efficiency but also bridges the gap between traditional motors and fully customized motion solutions, making them an ideal power choice for applications such as robotics, medical devices, drones, and high-precision industrial automation.